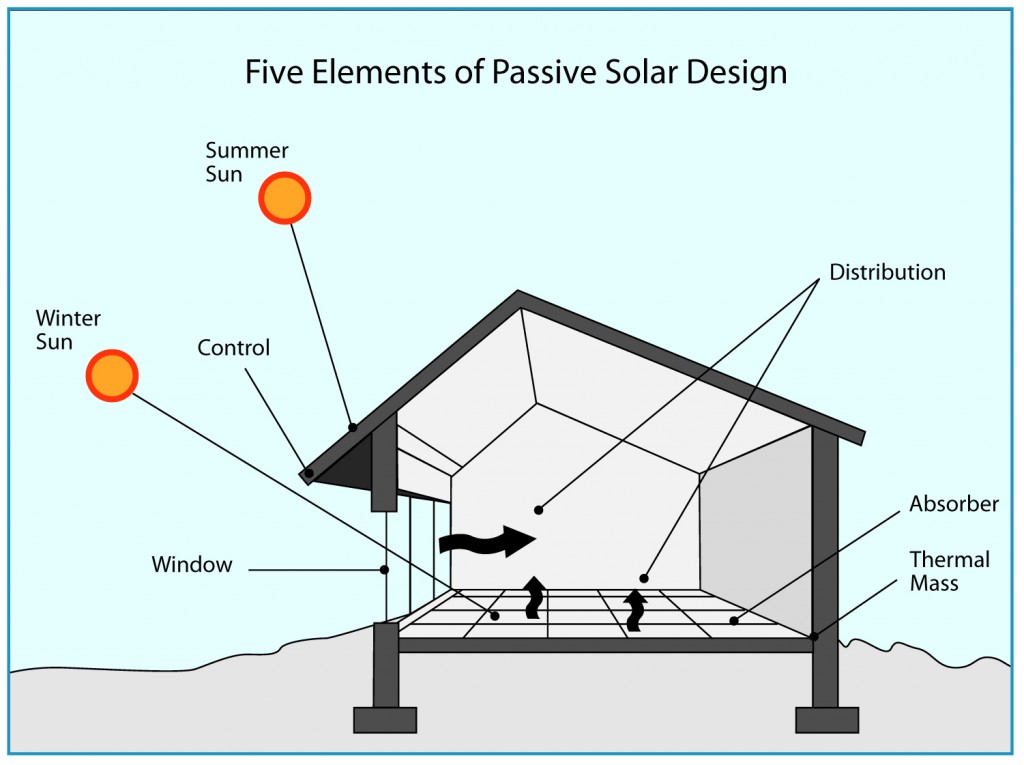

Passive Solar refers to a design strategy by which a house harvests the winter sunlight for heating. Because the sun is much lower in the sky during winter months (solar elevation is 22 degrees in winter but 67 degrees in summer), carefully calculated roof overhangs can allow south facing windows to be exposed to the sun during winter months, yet remain shaded during summer months. A thermal mass (usually in the form of a concrete floor or wall) is used to store the heat from the sunlight, which it then radiates as indoor temperatures begin to cool off at night.

My site location did not allow me to contemplate a completely passive solar design. I had to account for many days (or weeks) in a row of cloudy or snowy weather. Also, I had pine trees partially obscuring the sun in winter months. However, I did try to incorporate passive solar elements in order to reduce the amount of mechanical heating the house would require. It also allowed me to include a large bank of windows on the southern facade with no “energy penalty”. Although my windows were R5 (good for a window), they have almost no insulating value when compared to my walls at R37. But with the added heating benefit of winter sunlight, they made up for this deficiency in insulation value. So 41% of my glazing is on the south wall.

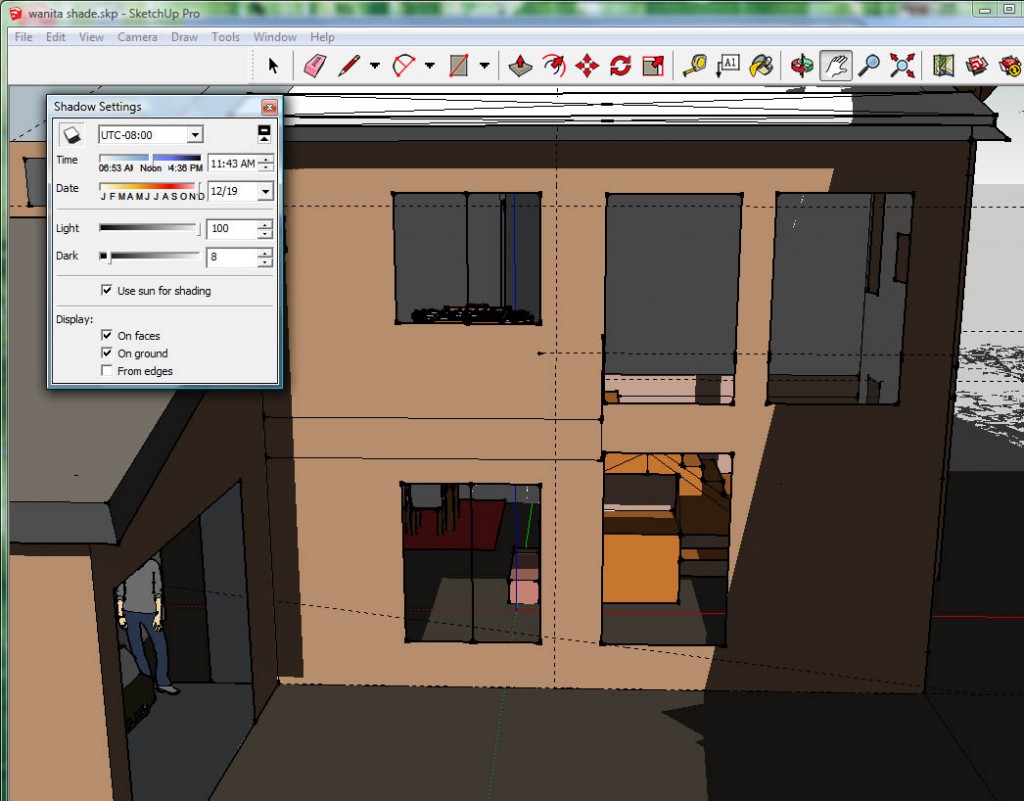

In order to position windows and design an effective roof overhang, I designed a simple model of the house using a CAD program called Sketchup. Then, by “placing” the model on its exact location inside Google Earth, I was able to see how the sunlight entered through windows at various times of the day during different months. This allowed me to carefully position windows and size the roof overhang above them to achieve optimal sun exposure.

Windows

Window glass is naturally transparent to visible light and high frequency solar radiation (ie, heat). However, these days most energy efficient windows have special Low-e coatings that reflect heat, so they keep the heat from the sun out, and the heat from the house in. I selected a special glass coatings for the windows on the south facade with high Solar Heat Gain Coefficients (0.62 center of glass measurement), to allow as much solar heat through the windows as possible. This coating still reflects low frequency radiation back into the house, yet is mostly transparent to high frequency solar radiation

Thermal Mass

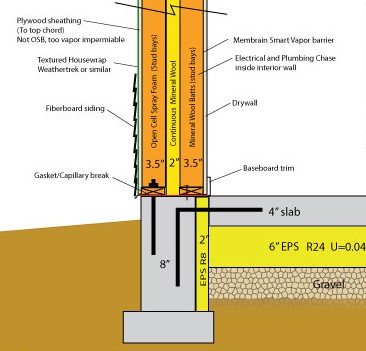

Passive solar works better when there is a large, insulated interior thermal mass that can absorb excess heat and re-radiate it when needed. In this case, my thermal mass was my foundation slab, 4 inches thick, covered with brown tile to absorb sunlight and insulated with 6″ of EPS foam underneath. Comprised of 330 cubic feet of concrete, as a thermal mass it can store around 7600 BTUs per Fahrenheit degree. This means as temperatures drop at night, the slab will act as a stored heat source, releasing 7600 BTUs of heat into the interior of the house for every degree in temperature drop. To put this in perspective, this is enough heat to keep the house comfortable, even when it is freezing outside. Of course, the concrete eventually cools off, but it can be recharged by sunlight and warm air from mechanical heating.